WhatsApp: +86 18126157548 Email: kerry@alpinemold.com

Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

| Table of Contents |

| 1.Introduction |

2.Tracing the Roots: The “Triad” Mechanism of Plastic Aging |

| 3.Systematic Solutions: From Design to Production – A Practical Guide to Prevent Plastic Aging |

4.Design Traps: 5 Common Misconceptions About Plastic Aging |

5.Success Case: Anti-Aging Upgrade for an Outdoor Smart Device Housing |

| 6.Conclusion |

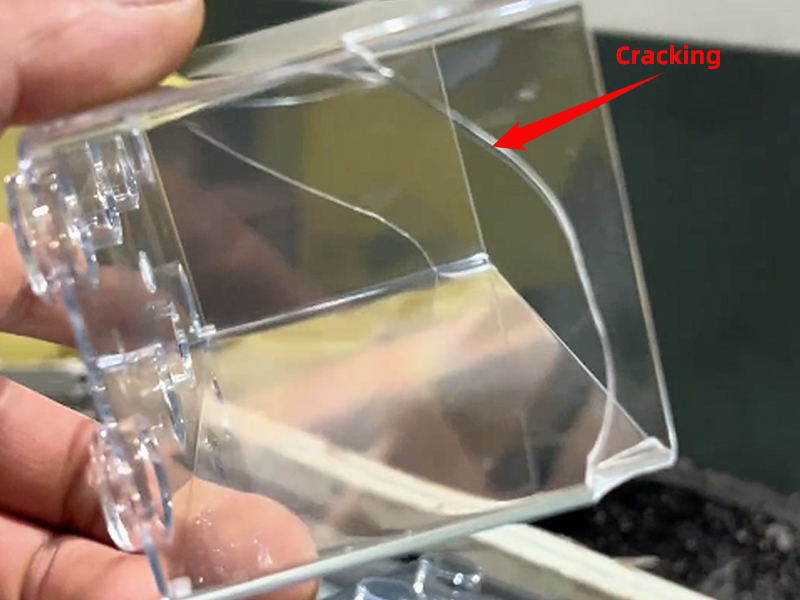

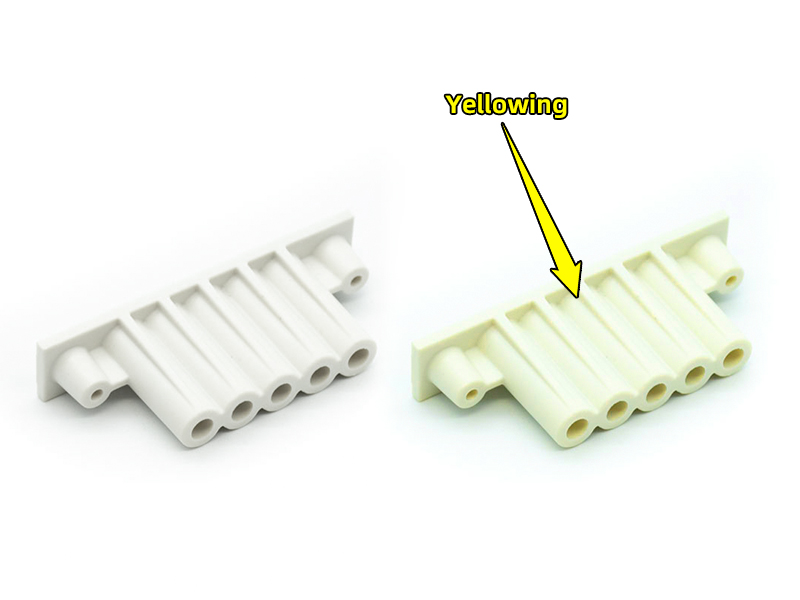

Another product recall, customer complaints about cracking and yellowing—sound familiar? For engineers and designers, plastic degradation isn’t just theory. It’s a real challenge that affects reliability, brand image, and profit. When plastic aging causes brittleness or color change, even great designs can fail early.

Choosing the right material and molding process is key. Yet with endless resin options and real-world variables, the question remains: how to prevent plastic aging and keep parts performing longer?

That’s where Alpine Mold comes in. As a professional mold and injection molding manufacturer, we help you delay plastic aging through smart material selection and optimized processing. This guide breaks down the causes of plastic aging—and shows practical ways to prevent it from design to production.

Plastic aging doesn’t come from a single cause. It results from a mix of factors — material composition, environmental exposure, and mechanical stress. Understanding this triad is key to delay plastic aging and keep products performing well over time.

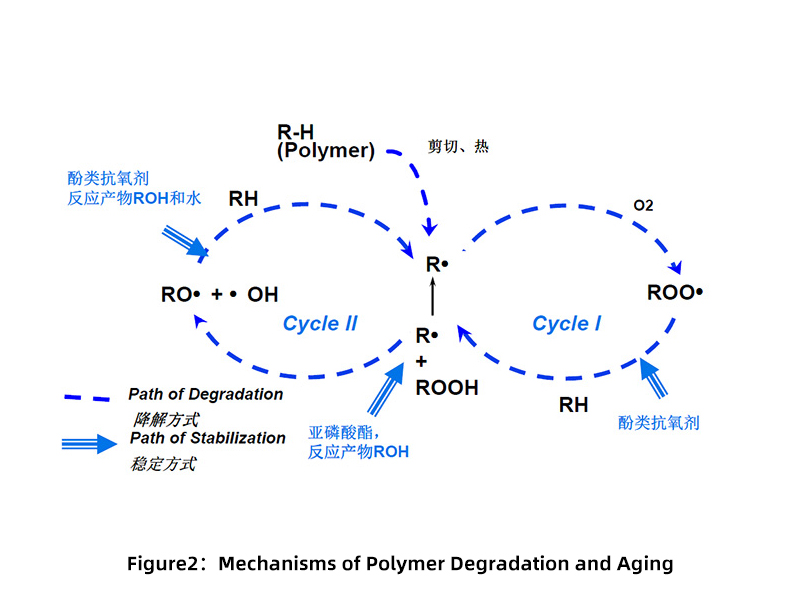

The intrinsic structure of a polymer plays a big role in how well it resists aging.

Usually, reactive molecular groups like double bonds and hydroxyls act as weak spots — that’s often where oxidation or chain scission first start.

When the molecular weight distribution is relatively narrow, the polymer tends to stay more stable and less likely to go through plastic degradation.

A moderate degree of crystallinity also helps, since it can block oxygen and light from getting into the polymer matrix. But if crystallinity goes too far, the material may slowly turn brittle and even crack when stressed.

Environmental factors can speed up degradation much more than what the material data sheets might lead you to believe.

Actually, UV radiation in the 280–400 nm range has enough punch to break polymer chains, which often shows up as color fading, embrittlement, or that chalky surface look.

As shown in Table 1, this wavelength range carries enough energy to snap common chemical bonds — like C–H, C–C, and C–O — and that’s what eventually drives plastic degradation.

Table 1. Bond Energies of Common Chemical Bonds and Corresponding Light

Energies at Different Wavelengths

| Wavelength (nm) | Light Energy (kJ/E) | Bond Type | Bond Energy (kJ/mol) |

|---|---|---|---|

| 290 | 419 | C–H | 380–420 |

| 300 | 398 | C–C | 340–350 |

| 320 | 375 | C–O | 320–380 |

| 350 | 339 | C–Cl | 300–340 |

| 400 | 297 | C–N | 320–330 |

When the temperature rises, molecules move faster, which naturally speeds up oxidation and thermal degradation.

Moisture, on the other hand, tends to trigger hydrolysis — especially in polymers with ester or amide bonds, like PBT, PET, and PA. That’s when you start seeing a drop in molecular weight and a loss of strength.

And when heat, humidity, and UV light work together, they form a powerful mix that really pushes UV degradation of plastics, cutting down the material’s lifespan.

As shown in Figure 2, this process goes through radical chain reactions (Cycle I and Cycle II) that keep the oxidation and plastic degradation going under both heat and UV exposure.

Mechanical stress — whether it comes from service loads or leftover molding stress — often works like a hidden engine driving plastic aging.

Constant tensile stress can slowly realign molecular chains and form tiny microstructural defects, while cyclic or impact stress speeds up fatigue, letting cracks spread more easily.

Even the residual stress left from the injection molding process itself can quietly push plastic degradation forward, even when the part still looks perfectly stable on the surface.

What Engineers Should Pay Attention To

Engineers and designers aiming to extend plastic lifespan should not treat aging as a single-variable issue.

Instead, it’s vital to evaluate:

The chemical structure and stabilizer package of the chosen resin,

The combined effect of UV, heat, and humidity in real-life conditions.

The residual stress generated during molding.

Only by integrating these considerations early in the design and manufacturing stages can one achieve effective plastic stabilization and prevent premature plastic aging or degradation in the field.

Following our understanding of how plastic aging occurs, the next step is to take systematic action.

In real-world projects, effective plastic stabilization is achieved only when design, material selection, additives, and testing are aligned.

Here’s how we approach it step by step.

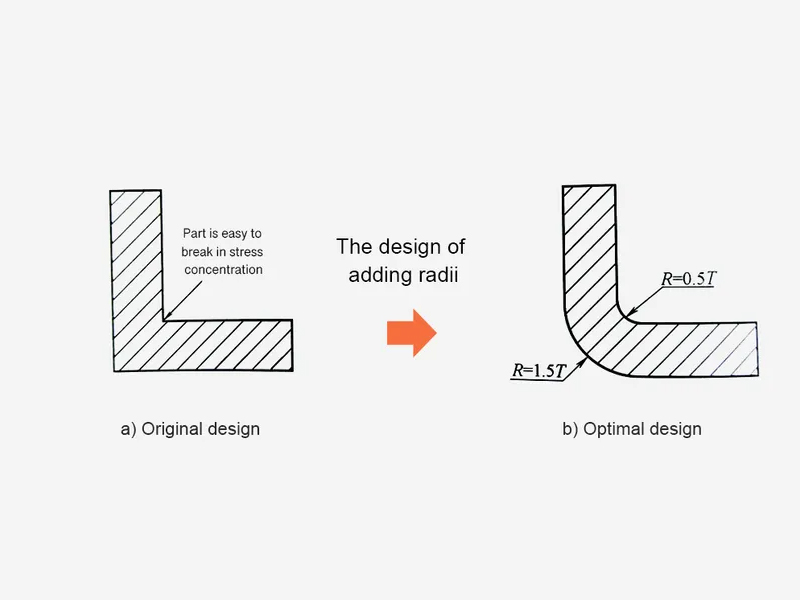

Design and tooling decisions are just as critical as material choice. Poor design can introduce internal stresses that silently accelerate plastic aging.

Best practices include:

Avoid stress concentration: Use generous radii on all corners to eliminate sharp edges that act as crack initiators.

Maintain uniform wall thickness: This promotes even cooling and reduces residual stress during injection molding.

Design ribs properly: Keep rib thickness between 50–70% of the nominal wall to prevent sink marks while maintaining stiffness.

Our Professional Perspective:

At Alpine mold, our tooling engineers conduct DFM (Design for Manufacturability) reviews before mold fabrication.

We carefully evaluate wall thickness transitions and part geometry to eliminate uneven shrinkage—one of the leading causes of stress-induced plastic degradation.

This preventive step alone can eliminate up to 80% of potential aging risks before production even begins.

No matter how advanced the base polymer might be, it still needs the right anti-aging additives for plastics to keep its performance steady out in real-world use.

Additive Type | Core Function | Mechanism of Action | Recommended Dosage | Commonly Used In |

Antioxidants | Inhibit thermo-oxidative degradation and delay plastic aging | Scavenge free radicals generated by heat or oxygen exposure | 0.1–0.8% | PA, POM, PE, PP, PC |

UV Stabilizers | Protect against UV degradation of plastics | Absorb or dissipate UV energy before it breaks polymer chains | 0.2–1.0% | ASA, PMMA, PC/ABS, outdoor housings |

Anti-Hydrolysis Agents | Prevent hydrolytic cleavage of ester and amide bonds | React with or neutralize water molecules to protect the polymer backbone | 0.2–0.5% | PBT, PET, TPU |

Hindered Amine Light Stabilizers (HALS) | Long-term protection against photo-oxidation | Regenerate themselves after UV exposure, offering sustained effect | 0.1–0.5% | PP, PE, TPO, automotive parts |

Metal Deactivators | Protect plastics exposed to metal contact (e.g., cables, connectors) | Chelate metal ions that catalyze oxidation | 0.1–0.3% | PA, PE in electrical components |

Combined Masterbatch Systems | Integrated solution for overall plastic stabilization | Tailored blend of antioxidants, HALS, and UV absorbers for specific conditions | Custom | Custom compounding, outdoor and automotive products |

Our Professional Perspective:

Through our trusted supplier network, Alpine Mold can tailor masterbatch formulations to fit your geographic region, operating temperature, and cost-performance ratio.

That way, every dollar you put into additives goes straight toward better plastic stabilization and a longer material lifespan.

Even the best design needs validation. That’s why accelerated plastic aging tests are indispensable for engineers who want reliable data instead of assumptions.

Key testing methods include:

QUV test – Simulates cyclic exposure to UV light and condensation for UV degradation of plastics evaluation.

Thermo-oxidative aging test – Assesses long-term heat resistance and oxidative stability.

Hydrolysis test – Evaluates mechanical property retention under high humidity conditions.

Our Professional Perspective:

At Alpine mold, every new mold undergoes “graduation testing” in our in-house lab before mass production.

We quantify color change (ΔE), tensile strength retention, and surface gloss to provide clients with a scientific prediction of service life—minimizing warranty risks and ensuring dependable product quality.

What Engineers Should Pay Attention To

For engineers trying to prevent plastic aging, it’s better to see the task as a system-level design challenge rather than something to fix after production.

Real plastic stabilization takes a mix of smart choices and consistent practice:

• Choose materials based on their environmental exposure,

• Design both the part and mold to minimize stress,

• Use the right anti-aging additives, and

• Run quantitative testing to confirm real-world performance.

When these steps are applied together, plastic aging can be slowed down, product lifespan extended, and the result is a more durable, reliable product that keeps performing year after year.

❌Myth 1: “Plastic aging simply means becoming brittle.”

Fact: Plastic aging happens when molecular chains either break (chain scission) or bond together (cross-linking). When the chains break, the material turns brittle; when they link up too much, it tends to harden, crack, or lose flexibility. Interestingly, some plastics—like PVC—can even go the opposite way, turning soft and sticky over time because of plasticizer migration.

Our professional insight:

In one of our consumer electronics projects, we actually ran into this issue. The parts started losing gloss and became slightly tacky after long-term storage. After testing a few options, we fixed it by switching to a stabilized ABS formulation and fine-tuning the additive retention process during molding. That small change made a big difference in long-term surface stability.

❌ Myth 2: “Adding antioxidants is enough to prevent aging.

Fact: Antioxidants mainly guard plastics against thermo-oxidative degradation. But if the part also needs to handle UV radiation or hydrolysis, that’s a different story — you’ll need light stabilizers or anti-hydrolysis agents specifically designed for those conditions.

Our professional insight:

In our material database, we keep several stabilized grades of engineering plastics on file. For instance, when working with automotive components that face long-term high temperatures, we’ve found that using a PPA compound with high-temperature antioxidants and copper inhibitors delivers much better reliability than the usual standard grades. It’s one of those tweaks that quietly but significantly extends part life in harsh environments.

❌ Myth 3: “Indoor plastics don’t age.”

Fact: Even when parts are used indoors, they’re not completely safe from degradation. I’ve noticed that blue light from LED screens, thermal cycling from nearby electronics, and even humidity swings from air conditioning can quietly speed up the aging process over time.

Our professional insight:

In one of our smart home controller housing projects, we ran an accelerated aging test to mimic about five years of indoor light and heat exposure. The PC/ABS formulation held up impressively well—no color fading, no loss of impact stability—which gave our client solid, data-backed confidence in the product’s lifespan.

❌ Myth 4: “Virgin materials always age better than recycled ones.”

Fact: The aging resistance of plastics really comes down to things like molecular integrity, stabilizer content and retention, and even the processing history—not just whether the resin is virgin or recycled. I’ve seen that sometimes a well-stabilized recycled grade can actually perform better than poorly processed virgin material.

Our professional insight:

We’ve always supported sustainable manufacturing. When we work with high-quality recycled polymers, we don’t just assume they’re ready to go—we run rheological and chromatographic tests to check for any molecular degradation. After that, we tweak the formulation and processing parameters until the final parts show durability close to that of virgin materials.

❌ Myth 5: “Lower temperatures mean slower aging.”

Fact: While lower temperatures slow chemical reactions, they can cause low-temperature embrittlement. Under stress, plastics may fracture due to reduced toughness rather than chemical degradation.

Our professional insight:

For outdoor products used in cold climates, UV resistance is only part of the equation. Selecting materials with low glass transition temperature (Tg) and high impact strength—such as modified TPU or toughened PP—is key to preventing cracks during winter assembly or use.

Design Takeaway

Understanding the mechanisms behind plastic aging allows engineers to make smarter design and material decisions.

Incorporating the right stabilizers, ensuring uniform wall thickness, and validating material behavior through accelerated thermal and UV testing (ISO 4892 / ASTM D4329) can greatly extend part lifespan before mass production even begins.

An industrial client’s outdoor smart device housing, originally made of PA66, suffered from plastic degradation and plastic aging — surface chalking, fading, and severe strength loss appeared within just one year of outdoor use. The customer had initially worked with another supplier, but the results failed to meet performance expectations, leading to premature product failure and high maintenance costs.

Our Analysis and Solution:

When the client approached Alpine Mold, our engineering team conducted a complete material and process review, identifying the root causes behind the rapid degradation. We implemented a comprehensive solution:

Material Replacement: Replaced hydrolysis-prone PA66 with weather-resistant ASA to delay plastic aging and reduce UV-induced degradation.

Formulation Enhancement: Added tailored anti-aging additives, including UV absorbers and HALS, for effective plastic stabilization and extended lifespan.

Process Optimization: Adjusted drying and molding parameters to minimize plastic degradation during processing and ensure consistent part quality.

Results:

After QUV accelerated weathering tests equivalent to three years of outdoor exposure, the housing maintained a color difference (ΔE) within 2.0 and retained over 85% of its mechanical strength. The client successfully entered stable mass production with significantly lower after-sales costs.

Conclusion:

Plastic aging is a complex process — it’s not just about time passing. It’s affected by molecular structure, the surrounding environment, and even the way the product is designed. You can try switching materials or adding anti-aging additives, and sure, that might help for a while. But honestly, those fixes rarely solve the deeper problem behind plastic degradation. Real durability, in our experience, starts right from the design stage.

At Alpine Mold, we’ve learned that prevention begins long before production kicks off. Our engineers bring decades of hands-on experience in injection molding, material optimization, and part design, working together to slow down plastic aging from the inside out. By weaving anti-aging strategies into the early design phase, we help you cut down development time, lower production costs, and achieve consistent long-term performance.

If you’re designing a new plastic part — or dealing with one that’s already showing signs of wear — we’re here to help.

Get in touch with Alpine Mold today. Let’s design, mold, and build plastic components that truly stand the test of time.