WhatsApp: +86 18126157548 Email: kerry@alpinemold.com

Views: 0 Author: Danny Publish Time: 2025-12-30 Origin: Site

An injection mold is not defined by a single label; it may belong to multiple categories simultaneously. For instance, a mold could be a single-cavity mold, a cold runner mold, and a two-plate mold, while also possessing mass production capabilities. If you select the wrong mold type from the outset, it will not only increase costs and delay delivery schedules but may even directly impact the success or failure of the entire project. This guide will explore 15 types of injection molds, helping you better understand which projects each is truly suited for.

| Table of Contents |

| 1.2 Based on Production Volume |

2. How to Choose the Best Injection Mold Type for Your Product? |

A plastic injection mold is a specialized tool used for mass-producing precision plastic components, typically made from steel or aluminum metal materials. Selecting the correct mold type is crucial because it directly impacts a project's production costs, surface finish quality, and molding efficiency. Moreover, different mold structures influence plastic flow patterns, cooling rates, demolding methods, and mold lifespan. Therefore, thoroughly understanding mold classifications during the project's early stages is essential. This article introduces 15 types of injection molds according to five dimensions: number of cavities, production volume, feeding system, mold plate structure, and functional mechanisms.

To understand injection molds, we begin with the most fundamental and intuitive classification method: by the number of cavities. A “cavity” refers to the internal area within the mold that forms the product's shape. The number of cavities determines how many products an injection molding machine can produce simultaneously in a single cycle. This not only impacts production efficiency and unit cost but also influences the mold's structural complexity and overall investment.

Definition and Features: A single-cavity injection mold refers to an injection mold designed with only one product forming area, where all injection pressure and material in each cycle are concentrated on producing a single part. Its structure, runner system, and cooling system design are relatively simple, aiming to ensure optimal molding quality for this sole plastic component. When issues arise, single-cavity molds are easier to diagnose and repair, resulting in lower maintenance costs.

Advantages and Limitations: Single-cavity injection molds feature lower manufacturing costs and shorter development cycles, making them highly suitable for small-batch orders, highly customized projects, or products with short lifecycles. They enable rapid design validation and risk mitigation in the early stages. However, their drawbacks are equally evident—low production efficiency, as only one plastic part can be molded per cycle. During mass production, the unit cost per part becomes significantly higher than that of multi-cavity molds, as machine time and labor costs cannot be spread across more products. Therefore, single-cavity injection moulds emphasize quality stability, design validation, and early trial production rather than competing on output volume.

Appliances: Due to shorter flow paths and more uniform pressure and cooling distribution, single-cavity molds facilitate greater dimensional consistency, effectively enhancing the molding precision of plastic parts. They are particularly well-suited for large-sized products, those with significant wall thickness variations, or complex structures featuring deep cavities and intricate details. This is because they ensure smooth filling of molten plastic and reduce defects caused by flow imbalances.

Technical Case: Alpine Mold recently customized a large single-cavity injection mold for refrigerator door frame products, with mold dimensions reaching 2.4 meters × 1.5 meters. The product not only has an extra-large overall size but also requires strict structural rigidity and dimensional accuracy. Restricted by core technical indicators such as the injection molding machine's clamping force threshold, melt filling uniformity, and overall mold stress stability, the single-cavity design becomes the optimal solution balancing molding quality and production feasibility. It effectively avoids problems such as uneven filling and stress concentration that may occur with multi-cavity layouts, ensuring product tolerance control and mass production stability.

|  |

Definition and Features: Multi-cavity injection mold refers to a mold designed with multiple identical product molding areas within a single mold set, allowing the injection molding machine to produce multiple parts simultaneously in one molding cycle. As the number of cavities increases, the structure of multi-cavity molds becomes more complex and manufacturing difficulty rises. This requires stricter runner balancing, cooling design, and higher-grade steel and machining equipment. Since multi-cavity molds contain more molding areas, wear rates accelerate, necessitating more frequent cleaning and maintenance, which leads to higher overall maintenance costs.

Advantages and Limitations: Although multi-cavity molds have higher manufacturing costs than single-cavity molds due to their more complex structure and higher precision requirements, they offer significant advantages in terms of production efficiency and unit cost. Simultaneously molding multiple products significantly reduces unit costs and enables fast delivery. Therefore, multi-cavity molds are preferred for increasing production capacity, lowering unit costs, and meeting the demands of large-scale mass production.

Appliances: Multi-cavity molds are ideal for products with high demand, requiring stable production, fast cycle times, and uncomplicated dimensions—such as daily necessities, medical consumables, packaging products, electronic components, and small automotive functional parts. By producing multiple identical items in a single injection cycle, they significantly boost output capacity and reduce unit costs, making large-scale production more economical.

Case Sharing: To meet the high-yield demand for disposable medical products (with the customer's large annual output scale), multi-cavity injection molds become the optimal solution for matching production capacity goals. Alpine Mold initially customized a 4-cavity mold to match the customer's initial needs, and later upgraded to an 8-cavity solution as the customer's annual output continued to grow. By improving single-mold output efficiency, it accurately meets the expanding production capacity requirements.

|  |

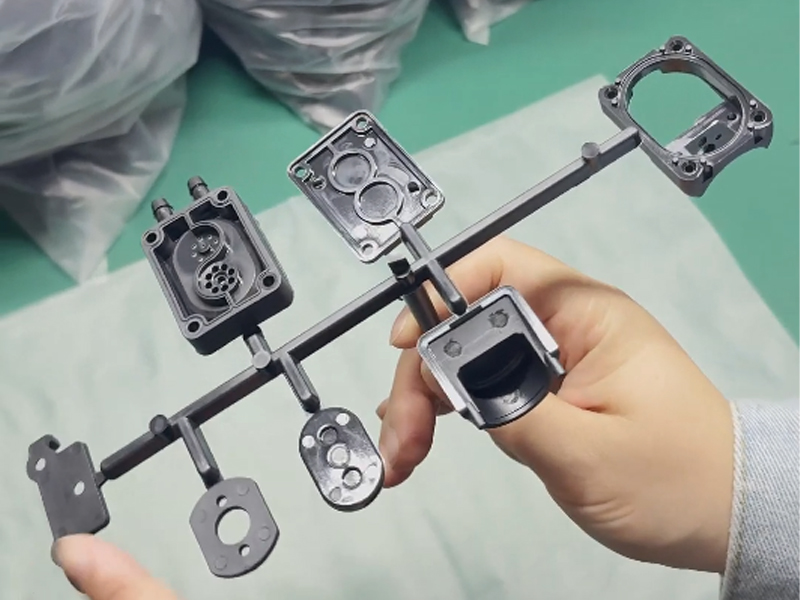

Definition and Features: Family mold, also known as family tooling or Multi-component mold, refers to a single mold containing two or more cavities for products of different shapes and sizes. All products share the same runner system, enabling multiple distinct parts to be formed simultaneously in a single injection cycle. Family molds are highly suitable for producing complementary components, such as manufacturing upper and lower covers, left and right structural parts, or different models of small sub-assemblies within one mold.

Advantages : The primary advantage of family molds lies in their significant cost reduction: compared to producing multiple separate molds, they can save approximately 30-50% in mold costs. Additionally, manufacturing all parts within the same cycle ensures consistent color, material properties, and shrinkage rates, thereby enhancing overall assembly fit.

Limitations: However, family molds also have limitations. They are unsuitable for products with significant variations in shape, size, or wall thickness, as this can lead to challenges in balancing injection filling and cooling. Furthermore, if an issue arises in any single cavity, the entire mold must be shut down for maintenance, resulting in lower production flexibility. Therefore, family molds primarily emphasize reducing mold costs, ensuring consistency among matched components, and enabling the simultaneous production of multiple different products in a more economical manner.

Case Sharing: A customer specializing in air pumps had a product consisting of seven to eight components that needed assembly. To reduce production costs, the customer proposed integrating the entire set of products into one family mold. Alpine Mold conducted an in-depth analysis of the structural characteristics and molding process compatibility of each component, and finally determined that some core components could be integrated into a single mold design. This integrated solution not only accurately met the customer's cost control needs but also simplified the subsequent assembly process and significantly improved supply chain efficiency.

Based on the production quantity, an injection mold can be classified into a prototype mold and a production mold.

Definition and Features: Prototype mold, also known as pilot mold or bridge tooling, is a type of injection mold used for product design validation, functional testing, or small-batch trial production. Typically made from materials such as P20, S45C or aluminum, these molds has a relatively short lifespan, usually less than 50,000 molding cycles.

Advantages and Limitations: The purpose of a prototype mold is not “long-term production,” but to address “uncertainty.” Its advantages include a short development cycle and low mold cost. The mold structure is also relatively simple, typically featuring: single-cavity molds, cold runner systems, and two-plate molds.

Appliances: Particularly suitable for products in the early stages of new product development where uncertainty exists, market size is unstable, and initial sales testing is desired; for products with complex structures and higher risks; or when customers have not finalized the design version and may require actual injection-molded parts for functional testing. However, prototype molds are not suitable for products already confirmed for long-term mass production, nor for products requiring extremely high stability in appearance and dimensions.

Definition and Features: Production mold, also known as production tooling, is a kind of injection plastic mold specially for long-term demand of large batch stable production. The production mold is generally made of high grade steel, 136/S136/ P20/ H13/ P20/ 718 / 718H etc. Its mold lifespan is relatively long, generally 300,000, 500, 000, 1,000,000, or even more than 2,000,000 shots.

Advantages and Limitations: Production mold is designed for mass production, addressing manufacturing efficiency and stability. Its advantages include low per-unit costs, long-term stable production, high quality consistency, and support for automation. Disadvantages include high initial mold costs, extended development cycles, and stringent requirements for design maturity.

Appliances: Production molds are suitable for manufacturing products with clearly defined annual production volumes that demand high standards for appearance, functionality, and assembly precision. So It is highly suitable to make electronic product enclosures, smart home device housings, medical components, industrial parts, automotive accessories, and more.

Prototype Mold VS. Production Mold

Comparison Items | Prototype Mold | Production Mold |

Purpose | Validate product design, assembly, and functionality for rapid testing. | Enable long-term, stable, and efficient large-scale production. |

Mold Lifespan | Short lifespan, typically hundreds to thousands of shots, sufficient for sample production | Long lifespan, typically requiring hundreds of thousands to millions of shots, necessitating high wear resistance. |

Mold Material | Commonly uses standard steel (e.g., P20, S45C) or aluminum alloy to reduce costs and shorten machining time. | Must use high-hardness, high-wear-resistant steel (e.g., H13, S136, NAK80) with heat treatment. |

Mold Structure | Simplified design may omit or streamline complex components like sliders, inclined ejectors, or hot runners to shorten manufacturing cycles. | Complete and intricate structure incorporates all necessary core-pulling, ejection, cooling, and venting systems to ensure quality and efficiency. |

Cooling System | Simple (e.g., straight water channels) with lower cooling efficiency. | Carefully engineered (e.g., conformal cooling) to ensure rapid, uniform cooling and reduce cycle times. |

Cost and Lead Time | Low cost, short lead time (several days to three weeks), emphasizing speed. | High cost, long lead time (three weeks to months), representing a one-time large-scale investment. |

Application | Used in early stages such as design validation, exhibition samples, small-batch trial production, and market testing. | Used for formal large-scale, fully automated continuous production, serving as the core tool for product commercialization. |

Injection molds can be categorized into three main types based on the structure and operating principles of their feeding systems: cold runner molds, hot runner molds, and stacked molds. The choice of runner system directly impacts material utilization, product surface quality, and mold manufacturing costs, making the selection of the appropriate runner configuration critically important.

Definition and Features: Cold runner molds refer to injection molding structures where the plastic material in the runner system cools during each molding cycle and is ejected together with the product. Its defining feature is that the runners require no heating or heat retention, solidifying directly alongside the product—hence the name “cold runner mold.” Cold runners primarily consist of a main runner, sub-runners, gates, and a runner balancing system.

Advantages and Limitations: Cold runner molds feature relatively simple construction, eliminating the need for complex heating systems like temperature controllers and hot runners. Consequently, their mold costs are lower compared to hot runner molds, and maintenance expenses are reduced. However, cold runner molds have limitations. Each molding cycle generates runner material waste, resulting in significant material loss. They are also unsuitable for expensive materials such as PEEK or PA12. Additionally, their molding cycles are longer, and automation levels are lower than those of hot runner molds.

Appliances: Cold runner molds are suitable for small to medium-volume production, particularly for single-color standard plastic parts, industrial structural components, internal parts for home appliances, automotive interior components, daily necessities, toy parts, and similar applications.

Definition and Features: Hot runner molds refer to mold structures in injection molding where the internal runner system maintains a constant high temperature, keeping the plastic in a molten state within the runners. Hot runners primarily consist of hot nozzles, hot runner plates, heating rods, temperature controllers, and insulating plates.

Advantages and Limitations: Compared to cold runner molds, hot runners eliminate solidified runner material in each molding cycle, eliminate the need for runner trimming, and support fully automated production. This results in significant savings in material costs and reduced labor expenses. They also produce no sprue marks and exhibit fewer cosmetic defects. However, hot runners have drawbacks. Their design and machining are relatively complex, requiring expensive hot runner systems, which increases mold costs. Maintenance is also more challenging and costly.

Appliances: Hot runner molds are suitable for medium to large-volume production of injection molded products with high aesthetic requirements, expensive materials, high dimensional stability requirements, and a high degree of automation, such as bottle caps, disposable medical supplies, transparent parts, engineering plastic parts, gears, sliders, and small mechanical structural components.

Cold Runner Mold Vs Hot Runner Mold

Comparison Items | Cold Runner Mold | Hot Runner Mold |

Core Principle | The runner cools down with the product and becomes waste material | The runner is continuously heated, keeping the plastic molten |

Applicability | Highly versatile, suitable for all materials | Requires materials with high thermal stability |

Molding Cycle | Longer cycle | Shorter cycle |

Material Utilization | Low, generates runner waste | High, almost no waste |

Appearance Quality | Visible gate marks | Achieves a seamless appearance and uniform quality |

Cost Structure | Lower mold cost, but more material waste | Higher mold cost, but saves material in the long run |

Application | Small batches, multiple varieties, R&D prototyping | Large-scale production, stable production, high demands on appearance |

Definition and Features: An insulated runner mold is a special injection mold system that falls between "cold runner" and "hot runner" systems. It utilizes thick-walled runners, high-temperature mold temperature controllers, and special insulation structures to keep the plastic in the runners in a molten or semi-molten state throughout the molding cycle.

Advantages and Limitations: Although insulated runner molds are not completely sprue-less like hot runner molds, they produce very little waste. They do not require expensive heating components and temperature controllers, so their mold cost and maintenance costs are lower than those of hot runner molds However, these molds demand extremely precise mold temperature control and are unsuitable for producing high-gloss or transparent parts. They also impose strict material requirements, as poorly flowing materials cannot be processed effectively.

Appliances: Insulated runner molds are highly suitable for producing thin-walled, high-volume products such as food packaging lids, trash can lids, basic structural components, and similar items.

Injection molds are classified based on the number of mold plates and parting line configuration, and can be categorized into two-plate molds and three-plate molds.

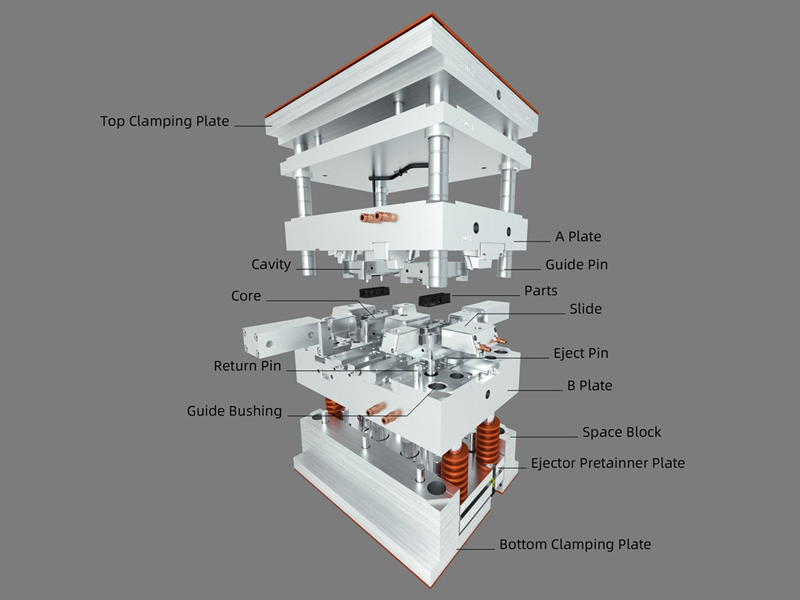

Definition and Features: Two-plate mold is the most common and basic mold structure. A two-plate mold is primarily composed of two main mold plates: the mold cavity and the mold core (also known as the A-plate and B-plate).

Advantages and Limitations: The two-plate mold features a simple structure with low machining and assembly complexity, making it suitable for most conventional injection-molded products. Its mold manufacturing cost is more economical than that of a three-plate mold. It is compatible with the vast majority of injection molding machines and offers convenient maintenance and cleaning. However, two-plate molds also have limitations: the product and runner are ejected simultaneously, requiring secondary separation; manual trimming of the sprue is necessary; and gate marks may appear on the surface.

Appliances: Two-plate molds are suitable for producing diverse plastic products, including electronic enclosures, home appliance housings, automotive shells, industrial structural components, toys, and daily-use tube fittings.

|  |  |

Definition and Features: A three-plate mold is an injection mold primarily composed of three plate structures: the front plate, middle plate, and rear plate.

Advantages and Limitations: Featuring two parting lines, three-plate molds most commonly employ point gates. Their gates separate automatically, eliminating manual gate trimming, thereby reducing labor costs and enhancing product quality consistency. However, compared to two-plate molds, three-plate molds exhibit greater structural complexity, demanding higher precision in mold design and machining. Consequently, they incur higher mold costs and present greater maintenance challenges. Three-plate molds are unsuitable for large components requiring substantial gate material, such as large PP parts.

Appliances: Three-plate molds are highly suitable for producing plastic products with high aesthetic requirements and small precision parts, such as high-gloss casings, cosmetic caps, transparent components, connectors, electronic buttons, and more.

|  |  |

Definition and Features: A stacked mold is a highly efficient injection mold structure composed of multiple cavities. Unlike traditional single-layer molds, it features two or more cavity layers stacked together, enabling the mold to produce double or multiple quantities of products in a single clamping cycle on the same injection molding machine. Stacked molds primarily consist of complex structures such as the front mold, intermediate plate, rear mold, hot runner system, and synchronized parting mechanism.

Advantages and Limitations: By doubling or multiplying output on a single injection molding machine, stacked molds offer lower production costs, higher automation levels, and significant advantages for mass production. However, due to their complex structure and high machining precision requirements, they demand extremely precise runner balancing and exceptionally high guiding accuracy, resulting in significantly higher mold costs. Additionally, hot runner materials are prone to scorching during downtime, and maintenance presents considerable challenges.

Appliances: Stacked molds are suitable for producing food lids, thin-walled containers, syringes, test kits, daily necessities, small high-volume parts, and more.

Injection molds are classified based on their functional mechanisms into thread-removal molds, core-pulling molds, slider molds, and inclined-piston molds.

Definition and Features: Unscrewing Mold is a specialized injection mold designed for producing injection-molded parts with threaded structures. It primarily employs mechanical, gear, chain, hydraulic, or servo motor drives within the mold to rotate the core, “unscrewing” the product from the threaded section for automatic ejection.

Advantages and Limitations: Unscrewing molds are particularly effective for producing deep threads or threaded structures prone to difficult ejection. It ensures consistent thread dimensions and features a highly automated demolding process, making it ideal for stable mass production at medium to high output levels. However, due to the high machining precision requirements and more complex internal structure of unscrewing molds, their manufacturing costs and subsequent maintenance expenses are relatively higher. Additionally, since products are demolded through rotation, the molding cycle is slightly longer than that of conventional molds.

Appliances: Unscrewing molds commonly employ three primary drive methods: mechanical gear drive, electric motor drive, and hydraulic or pneumatic motor drive. They are highly suitable for products demanding high thread precision, such as bottle caps, pipe fittings, threaded connectors, nuts, filters, and medical device threaded components.

Definition and Features: Collapsible Core Mold is a specialized injection mold designed for producing products with internal undercuts that cannot be ejected using rotational thread removal. It enables smooth part ejection by automatically retracting its multi-part cores during demolding.

Advantages and Limitations: Collapsible Core Molds eliminate the need for rotation during ejection, enabling rapid demolding with minimal risk of cosmetic damage. Their compact design ensures high precision on internal walls, making them ideal for producing small-sized products with deep undercuts. However, these molds demand exceptional precision, requiring more complex design and higher-accuracy machining equipment, resulting in higher tooling costs compared to standard molds or conventional screw-rotation molds. They are also unsuitable for large products or extremely deep undercuts.

Appliances: Collapsible Core Molds are particularly suited for manufacturing products with complex geometries such as internal threads, internal ring grooves, internal snap-fit mechanisms, and thin-walled deep thread structures. Examples include connector housings, precision snap-fit components, medical parts, and bottle caps with internal groove structures.

Definition and Features: A slider mold is a type of injection mold used to process undercut structures on the side of a product. It uses an automatic sliding core mechanism to facilitate smooth demolding of the product.

Advantages and Limitations: Slider molds effectively resolve complex lateral structures, enhance product design flexibility, and offer highly reliable mold construction with extended mold life. However, they also present drawbacks: more intricate mold structures, higher costs than standard molds, stringent machining precision requirements, susceptibility to jamming or flash leakage, increased mold space occupancy, and potential for larger mold dimensions.

Appliances: Slider molds are suitable for producing products with side holes, side buckles, side grooves, and L-shaped or T-shaped snap-fit structures, and are commonly used in automotive, medical, electronics, smart home and home appliance industries.

Definition and Features: A lifter mold is an injection mold used for handling small side undercuts. During ejection, it moves upward and outward along an inclined angle to release the undercut, allowing the product to be demolded smoothly.

Advantages and Limitations: The lifter mold structure is simpler than a slider mold, occupies less mold space, is easier to process, has a shorter lead time, and has lower mold costs. It offers stable operation and is easy to maintain. However, lifter molds are not suitable for deep undercuts or large-area side structures, as excessive angles may cause damage to the product.

Appliances: Lifter molds are particularly suitable for producing products with small undercuts, slanted structures, small step structures, or slightly open side structures, such as household appliance housings, small automotive decorative parts, partial snap-fit features in industrial parts, and small side clips in toy structures.

2. How to Choose the Best Injection Mold Type for Your Product?

In the product development and mass production process, selecting the appropriate injection mold type is a key step to ensure product quality, control manufacturing costs, and improve production efficiency. As an injection molding solution provider with 23 years of experience, Alpine Mold recommends following a systematic decision-making framework:

Product structural complexity is a core factor affecting the mold design form.

Simple-structured products: Regular injection molds with single parting lines and standard gates can be used.

Products with undercuts, deep cavities, thin walls, or snap structures: May require core-pulling mechanisms, side slides, angled ejectors, or multi-parting line designs.

Products requiring assembly of multiple parts: Family molds can be considered to ensure the consistency and assembly accuracy of matching parts.

Recommendation: Conduct DFM (Design for Manufacturability) analysis in the early stage of the project to effectively avoid rework and additional costs later.

Different production volumes determine the number of mold cavities and gating system type:

Production Scale | Optimal Mold Solution | Features |

Small-batch (< 10,000 pcs) | Single-cavity mold / Cold runner mold | Low cost, short development cycle |

Medium-batch (10,000–200,000 pcs) | Multi-cavity mold / Cold runner mold or hot runner mold | Reduced unit cost, improved efficiency |

High-batch (> 200,000 pcs) | Multi-cavity + Hot runner system | High stability, material saving, low long-term cost |

Products with high appearance requirements and color difference sensitivity: Hot runner molds are recommended to ensure uniform melt flow and high color consistency.

Products with high structural precision requirements: Need to ensure runner balance, and use valve-gated hot runners if necessary to achieve controllable flow.

Cost-sensitive products with general appearance requirements: Cold runner systems are more economical.

Total mold cost = Manufacturing cost + Maintenance cost + Unit molding cost. When selecting a mold, attention should not only be paid to the mold opening price but also to the long-term service cycle:

Hot runners have high initial costs but save materials and labor in the long run, suitable for products with large batches and long life cycles.

Cold runner molds have low initial investment but generate sprue recycling costs, suitable for small and medium-batch projects.

This article introduces 15 types of injection molds, covering nearly the entire spectrum from basic structures to high-precision core-pulling mechanisms and high-capacity systems. It also explains the unique applications and advantages of each mold type. By understanding these15 types of injection molds classification, you can more accurately determine which injection mold best suits your product, enabling your project to advance more efficiently and controllably.

With 24 years of specialized mold-making expertise and a team of over 200 employees, Alpine Mold has successfully delivered more than 10,000 high-quality injection molds. We maintain long-term partnerships with numerous renowned companies, earning industry trust from clients like Siemens, BMW, Michelin, and Magna. Based on your product structure, materials, and production targets, we can select the most suitable mold type and provide optimal injection mold solutions! Send us your drawings for a quote and technical consultation!

4.1 What is the Difference Between a Two-plate Mold and a Three-plate Mold?

Their main difference lies in mold cost, the number of parting surfaces, and the method of separating the product from the runner.

The two-plate mold features a simpler structure and lower mold cost. It has only one parting surface, and when the mold opens, the runner typically cannot separate automatically from the product.

Three-plate mold features a more complex structure and higher mold cost. It incorporates two parting lines, requiring the mold to open in two stages. This design enables automatic separation of the product from the runner.

There is no fixed price for an injection mold, as it is influenced by numerous factors such as product complexity, materials, cavities, mold life, machining equipment, labor costs, and more.

Prototype mold: 2-3 times cheaper than production molds

Simple production mold: $2,000–$5,000

Complex or high-precision production mold: $5,000–$30,000+

Large or multi-cavity production mold: $10,000 + or even more

The lead time for injection molds depends on the part design complexity, size, precision, molding material, number of cavities, mold material selection, and production quantity and more.

Prototype molds typically take 1-3 weeks.

Simple production molds generally require 4-6 weeks.

Complex or high-precision production molds usually take 5-10 weeks.

Large or multi-cavity production molds typically require 6-15 weeks or longer.

4.4 How Long Do Injection Molds Last?

The six core factors determining the lifespan of injection molds include: mold material, molding material, mold structural design level, machining precision and equipment, compatibility with injection molding machines, and mold maintenance and upkeep.

Prototype Mold lifespan: 1,000–50,000 shots

Soft Tooling lifespan: 50,000–300,000 shots

Production Mold lifespan: 300,000–1,000,000 shots

Hardened Steel Mold lifespan: 1,000,000+ shots