WhatsApp: +86 18126157548 Email: kerry@alpinemold.com

Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Two-shot molding, also known as dual-color injection molding, multi-color injection molding, or 2K injection molding, is a kind of injection processing approach with ultra-high precision, which is engineered to fabricate intricate components consisting of two distinct types of raw materials within an uninterrupted, single production sequence. In contrast to the conventional assembly procedures for multi-component products, this advanced technique enables a fully integrated production mode that dispenses with manual operational involvement as well as any supplementary post-manufacturing treatment procedures.

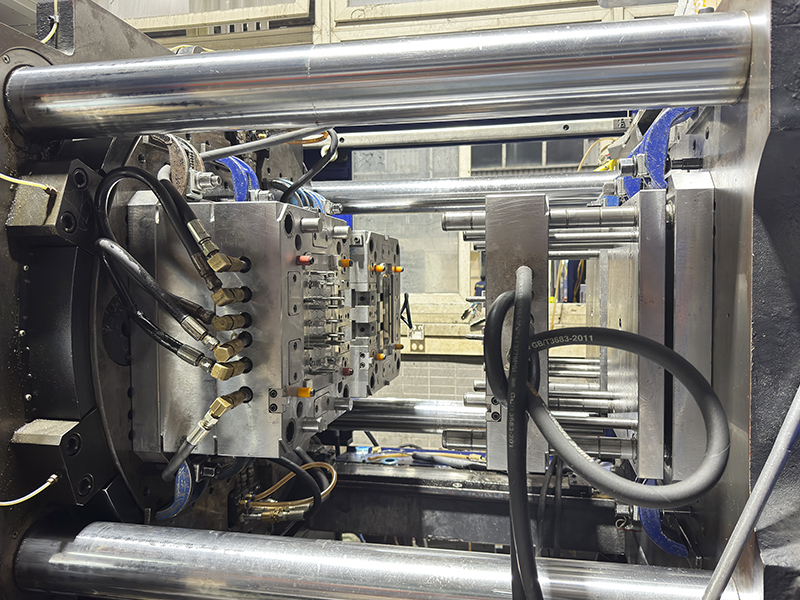

The process relies on specialized machinery equipped with two independent injection units and a rotating or sliding mold. Here is a step-by-step breakdown of how the two-shot molding cycle operates:

First Injection: The cycle begins similarly to standard injection molding. The primary material (typically a rigid plastic) is injected into the first mold cavity to form the base, or substrate, of the component.

Mold Rotation: After the substrate has cooled sufficiently to retain its shape, the mold opens. The rotary platform then rotates the substrate by 180 degrees, transferring it precisely to a second mold cavity.

Second Injection: The mold closes, and the secondary material (often a soft elastomer like TPE or a contrasting colored plastic) is injected directly onto or around the substrate. This stage occurs while the substrate still retains residual heat.

A major advantage of this process is that because the second layer of material is injected while the first layer still retains residual heat, this heat facilitates an extremely strong chemical or physical bond between the two materials. This "molecular-level" bonding prevents delamination or separation risks that might occur in later assembly.

Overmolding is a specialized molding technique that encases one material with another. Typically, a rigid plastic forms the base layer, while a flexible plastic or elastomer is molded over it. This process boosts product functionality, elevates aesthetics, and enhances tactile feel.

The overmolding process typically includes the following key steps:

Base Substrate Injection: The process begins with injecting the base material, typically a rigid plastic, into a mold to form the initial substrate.

Transfer of the Substrate: After the base substrate is formed and cooled, it is transferred to a second mold cavity.

Overmolding Material Injection: The second material, often a flexible plastic or elastomer, is then injected over the base substrate. This creates a bond, which can be either mechanical (through interlocking features) or chemical (for compatible materials).

Cooling and Ejection: Once the overmolded material has cooled and solidified, forming a strong bond with the base, the finished part is ejected from the mold.

Overmolding offers excellent compatibility; it can combine not only hard and soft plastics but also easily integrate plastics with metal inserts. Because it doesn’t require complex rotating mold equipment, overmolding has relatively low mold costs and allows for more flexible design modifications.

Two-Shot molding: This technique is primarily dedicated to the fusion of two distinct substances, which usually differ from each other in terms of physical characteristics, color schemes, or surface textures. Typical material pairings encompass thermoplastics with varying degrees of hardness or different hues, along with elastomers, nylon materials, and soft-touch resin compounds.

Overmolding: This technology demonstrates exceptional adaptability regarding the range of applicable raw materials, particularly when interacting with substrates that do not fall under the plastic category. One key merit of the overmolding method lies in its capability to effortlessly encase metallic inserts, screws, circuit boards, and even pre-fabricated molded components within a plastic layer.

Material compatibility serves as a core determinant of structural stability for multi-component integrated assemblies. For either two-shot molding or overmolding processes, verifying that the two disparate materials can form a tight interface with strong anti-delamination capacity is a prerequisite for the successful implementation of the design scheme. Nevertheless, the fundamental mechanisms through which these two molding technologies achieve effective material bonding vary substantially from one another.

Two-shot molding: Given that this technique necessitates injecting the secondary material promptly while the initial layer remains molten and incompletely cooled, the two substances must demonstrate excellent thermodynamic and chemical compatibility. For certain material combinations, pre-treatment procedures or specialized adhesive agents may be required to secure robust interfacial adhesion.

Overmolding: Compared with two-shot molding, overmolding exhibits more prominent flexibility in terms of material compatibility. In situations where the chemical bonding force between two kinds of materials is insufficient, technical personnel can fabricate grooves, undercuts, holes or knurled textures on the primary substrate. As the secondary material is injected into these prefabricated structures and completes the solidification process, the generated physical interlocking effect—similar to the fixing function of mechanical fasteners—can firmly lock the two material layers together. This distinctive characteristic allows overmolding to easily realize the combination of heterogeneous materials, and even to stably coat plastic layers on metal inserts, a technical effect that is difficult to attain via two-shot molding, which relies exclusively on chemical adhesion to achieve material bonding.

Two-shot molding: This technology is extensively utilized in the production of intricate parts characterized by diverse color schemes, surface finishes, or material property variations. Common use cases span across consumer electronics such as mobile phone housings, wearable devices, and Bluetooth earbuds, automotive parts like multicolored buttons and soft-touch grip components, as well as medical devices and instruments.

Overmolding: This method is widely used to make products that need better functionality, stronger grip, or reliable sealing. It’s commonly applied to everyday items like toothbrushes and electric drills, sports gear including golf club grips and bicycle handlebars, plus electrical connectors and industrial parts such as power plugs and valve knobs with sealing gaskets.

Two-shot molding:The mold system for two-color injection molding is a highly precise engineering integration. It typically requires the use of a dedicated two-color injection molding machine, and its core feature lies in the mold's rotating or moving mechanism. The most common configuration is a mold with a rotating platen that can rotate the core by 180 degrees. This requires the mold design to strictly adhere to the principle of symmetry to ensure that the dimensions and positions of the two mold halves are perfectly accurate.

Overmolding: This process uses standard injection molds to create the base material and adds some special features to accommodate the overmolding process. Compared to two-color injection molding, the mold design for overmolding is usually simpler because it only requires one material to be molded over another, without the need for multiple injection cycles.

Two-shot molding: By virtue of intricate geometric structure design and high-strength bonding protocols, this technology markedly elevates product quality standards—it not only enhances the functional performance and operational reliability of the end products but also preserves their intended visual aesthetics. It exhibits extensive material adaptability, being compatible with a diverse array of substances such as silicone, thermoplastics, elastomers, nylon and soft-touch resin materials, which in turn broadens the horizons for innovative product design. A core advantage of this process lies in its integration of two separate molding phases into a unified production cycle, which dispenses with the necessity of supplementary processing steps and thereby achieves tangible reductions in production duration and expenditure. This outstanding operational efficiency renders it a prime option for large-scale manufacturing operations, particularly in application scenarios that demand high output volumes and consistent product quality levels.

However, the initial investment is high, requiring significant capital for tool design, testing, and manufacturing. Subsequent mold modifications or iterations may be difficult due to cost constraints. Furthermore, the need to remove material from the injection molding machine after each production cycle results in longer single-cycle production times, making it less economical for small-batch production and less adaptable to flexible adjustments.

Overmolding:This process delivers superior product performance, with resin materials effectively reducing vibration and impact, improving chemical resistance, and providing excellent sealing and ergonomic design for a more comfortable grip.In terms of aesthetics, the method enables multi-color component integration and various surface finishing processes, satisfying the appearance criteria of premium products. It delivers high production efficiency and relatively low costs by eliminating secondary processing and streamlining the manufacturing workflow. Such flexibility makes it well-suited for small-batch production, especially for projects involving frequent design revisions or high customization demands.

However, it requires two separate production processes, resulting in a relatively longer overall production cycle. Insufficient temperature control or incompatible resin chemical properties may cause interlayer separation between the base material and overmolded layer, undermining product structural stability. Moreover, the process offers no notable efficiency and cost benefits in mass production, resulting in weaker competitiveness than alternatives such as two-color injection molding.

Two-shot molding | Overmolding | |

Materials & Substrate | Typically two thermoplastics molded in sequence (often color/texture or hard+soft) | Can overmold onto plastic, metal inserts, screws, PCB, or pre-molded parts—more material/substrate flexibility |

Bonding Mechanism | Relies mainly on material compatibility for thermal/chemical bonding (second shot on a warm first shot) | Uses mechanical interlock (undercuts, grooves, holes, knurls) plus possible adhesion—works well with dissimilar materials |

Mold & Equipment Requirements | More complex tooling, often needs a two-shot injection molding machine with rotary platen or index mechanism | Generally simpler tooling and can often run on a standard injection molding machine (depending on part and process) |

Production Efficiency & Volume Fit | One automated cycle for both shots—best for high-volume production and consistent quality | Often involves two steps—better for low-to-medium volume, frequent design changes, or customized parts |

Typical Applications | Multi-color / multi-texture parts with tight alignment: automotive buttons, consumer electronics housings, medical components | Soft-touch grip, sealing, vibration damping, insulation: handles, plugs/connectors, valve knobs, gaskets |

Selecting two-shot molding or overmolding requires a trade-off based on the core differences in product requirements. The decision can be analyzed from four key dimensions:

Process selection is primarily determined by the volume of production. When dealing with large-scale production, such as annual outputs reaching hundreds of thousands or more, two-shot molding presents substantial benefits. The automated nature of this process allows for continuous manufacturing with reduced cycle times, while the molecular bonding of materials guarantees consistent product quality, making it perfect for standardized, mass production. On the other hand, for lower or medium production volumes, like annual outputs in the range of several thousand to tens of thousands, or during prototype development, overmolding offers more design flexibility. It utilizes a less complex mold design, eliminating the need for intricate rotating mechanisms, and has reduced costs for mold adjustments when changing production runs, making it better suited for small-scale trials or design optimization.

Material selection is crucial for process compatibility. Two-shot molding requires chemically compatible materials, such as rigid plastics and soft elastomers (e.g., TPE), to ensure strong molecular bonding and prevent delamination. Overmolding is preferable for integrating metal inserts or combining dissimilar materials (e.g., plastics with metals), as it uses mechanical interlocking to create a physical bond. Additionally, two-shot molding has stricter requirements for material flow and shrinkage, while overmolding tolerates a wider range of material combinations.

Budget constraints are a key factor in process selection. Two-shot molding requires a higher upfront mold investment (about 2-3 times that of overmolding) but offers lower per-unit costs at high volumes. Overmolding is more cost-effective for budget-limited projects, as it has lower mold costs and no extra equipment needs, ideal for cost-sensitive SMEs. Note that overmolding’s per-unit cost may rise with volume, while two-shot molding’s per-unit cost falls as volume increases.

Design intricacy and iteration requirements influence process selection. Two-shot molding offers limited design adaptability: after mold finalization, material combinations and structural details are difficult to modify, making it suitable for established designs without frequent changes. For designs in the iteration phase, overmolding is more beneficial: its simpler mold design enables partial adjustments (e.g., base or overmold layer) and accommodates versatile material pairings—suited for rapid market response.

The choice must match the full product lifecycle: high-volume, chemically compatible, and design-stable products lean toward two-shot molding; low to medium-volume, dissimilar material integration, and design-flexible products are more suitable for overmolding. Through quantitative analysis of production volume, material traits, cost constraints, and design adaptability weights, a prudent decision balancing functionality and economic feasibility is achievable.

When determining the most suitable plastic moulding technology, although both two-shot molding and overmolding facilitate the combination of multiple materials, their distinct technical characteristics necessitate that the decision be guided by clearly defined priorities. Regardless of the specific method favored, a rigorous evaluation of manufacturing volume, material compatibility, fiscal constraints, and geometric requirements is indispensable. This analysis is vital to ensuring the final output achieves its functional goals while simultaneously optimizing cost-effectiveness and technical workability.

At Alpine Mold, 24 years of experience in two - shot molding and overmolding manufacturing is the core guarantee for delivering reliable solutions. We have successfully completed over 12,000 projects, accumulating rich technical expertise and being able to accurately grasp the process requirements of different products. Whether it’s two - shot molding or overmolding, we provide end - to - end full - lifecycle support—from design for manufacturability (DFM) and material selection to mold development, sample production, and stable mass production, offering one - stop coverage from concept to mass production.

If you have new part concepts or existing design plans, feel free to contact us at any time. Send your drawings, and we’ll provide professional quotes and customized solutions to help you efficiently bring your product to market.

Two-shot molding typically uses hard plastics (e.g., PC, ABS) paired with soft elastomers (e.g., TPE, TPU).

Overmolding also employs similar materials, often with metal inserts for enhanced functionality.

Costs vary by scale and design.

overmolding generally has lower upfront mold expenses than two-shot molding.

However, single-unit costs may rise due to manual steps or slower production speeds.

Key challenges include:

material incompatibility (risk of delamination),

longer production cycles (multiple independent steps),

stricter temperature/chemical compatibility requirements.

The primary alternative to overmolding is two-shot molding,

which integrates two materials in a single automated cycle via a rotating mold, offering similar multi - material capabilities but with different process workflows and cost implications.

Two-shot molding has shorter cycles (automated, single-step),

overmolding takes longer due to separate molding and transfer steps.