WhatsApp: +86 18126157548 Email: kerry@alpinemold.com

Views: 0 Author: Site Editor Publish Time: 2025-11-19 Origin: Site

| Table of contents |

| Inroduction |

| What Injection mold life expectancy Really Means |

Key Factors That Affect Injection Mold Lifespan |

SPI Mold Classification & Real-World Reference Table |

Common Mistakes That Shorten Mold Life — and How We Solve Them |

How to Choose the Right Mold for Your Project |

FAQ About Injection Mold Lifespan |

Conclusion: |

“How long does an injection mold last?” — it’s one of the first questions most customers ask when planning a new project.

And it’s a valid one — because an injection mold isn’t just a tool. It’s a long-term investment that determines your part quality, production cost, and delivery stability.

Over the past 20 years at Alpinemold, we’ve seen both sides of the story:

one customer’s mold runs smoothly for over a million shots, while another’s mold—made for the same type of part—starts showing flash and wear after just 50,000 cycles.

So what really causes this huge gap in injection mold lifespan?

The truth is, injection mold life expectancy depends on a combination of factors — from steel selection, design precision, and molding parameters to maintenance and production volume.

Yet, many companies underestimate how these details interact. For example, choosing the wrong steel grade for glass-filled materials or skipping preventive maintenance can silently shorten your mold’s life by half.

In this article, we’ll break down:

The real engineering factors that affect mold longevity

The SPI mold classification system and what it means in practice

Common mistakes that lead to early mold wear

And most importantly, how to choose the right mold material and structure for your production goals

By the end, you’ll know how to evaluate mold cost vs lifespan — and how a reliable manufacturer like Alpinemold helps you maximize both performance and ROI.

When we talk about injection mold lifespan, we’re really talking about how many molding cycles a tool can produce before it starts to affect part quality, efficiency, or tolerances.

But here’s what most non-engineers don’t realize:

Mold lifespan is not a fixed number — it’s a performance range defined by materials, design precision, and maintenance discipline.

For example:

A prototype aluminum mold might last only 100–1,000 cycles, just enough for initial testing.

A Class 103 P20 production mold may reach 100,000–500,000 cycles.

A Class 101 hardened steel mold, properly maintained, can easily exceed 1 million shots for mass production.

So when you see someone online say “our molds last 1 million shots,” that’s not a guarantee — it’s an engineering estimate based on how the mold is built and used.

The Real Definition of Injection mold life expectancy

Technically, injection mold life expectancy refers to the point when:

Dimensional accuracy of molded parts starts drifting out of tolerance;

Surface wear or corrosion appears on critical areas (e.g. cavity, gate, or ejector pins);

Maintenance frequency and cost rise beyond economical repair.

At Alpinemold, we define a mold’s end-of-life not just by failure, but by the point where consistent quality and cost-efficiency can no longer be maintained.

That’s why we analyze every project’s expected production volume and resin type before cutting steel — it’s the foundation of a reliable mold lifespan.

For example, here’s a real-world comparison from one of our customers in automotive interiors:

Both molds had identical geometry — but the one using glass-filled material required a hardened cavity and nitrided surface to resist abrasion.

Without that, wear at the gate and runner caused flash and dimensional drift much sooner.That’s why understanding how long a mold lasts starts from understanding what it will actually endure in production.

The lifespan of an injection mold isn’t determined by luck — it’s the result of engineering discipline.

After working with hundreds of molds over the past two decades, we’ve found that four key factors consistently determine how long an injection mold lasts: design, materials, manufacturing precision, and maintenance.

Good design is the first defense against premature wear.

When we design a mold at Alpinemold, we don’t just think about geometry — we think about how forces, heat, and resin behavior will affect the tool over time.

Common design flaws that shorten mold life include:

Underrated cooling system that causes uneven temperature and stress cracking

Thin parting lines that deform or leak under pressure

Sharp corners or poor gate design that lead to local stress

Ignoring moldflow analysis, resulting in imbalance and flashing

For example, a customer once sent us a multi-cavity consumer part mold originally designed without flow balance analysis. The result?

One cavity consistently over-packed, causing steel fatigue at the runner junction after only 60,000 cycles.

After we rebalanced the flow channels and improved venting, the new tool ran over 400,000 cycles without visible damage.

In short: a well-engineered design extends not only injection mold life expectancy, but also cycle time and product quality.

Choosing the right steel grade is like choosing the right heart for your tool.

The material you mold directly determines the abrasion, corrosion, and fatigue the mold must withstand.

Common Mold Steel | Typical Hardness (HRC) | Typical Lifespan Range | Recommended Use |

Aluminum | 20–30 | 500–5,000 shots | Prototypes, low-volume |

P20 | 28–34 | 100,000–500,000 shots | General plastics |

H13 | 48–52 | 500,000–1,000,000+ shots | Glass-filled or high-temp resins |

S136 / 420SS | 48–52 | 800,000+ shots | Corrosive materials (PVC, PC, etc.) |

Engineer’s Note:

We often see customers request P20 steel for glass fiber reinforced materials to save cost — but this is a common mistake.

Glass fibers act like sandpaper, and within a few months the gate and cavity surfaces start eroding.

In such cases, H13 or S136 hardened steel, sometimes with nitriding or coating, will actually be more cost-effective in the long run.

Even the best design and steel can fail if machining and fitting aren’t done precisely.

At Alpinemold, we use CNC, EDM, and wire-cutting machines with strict tolerance control — typically within ±0.01 mm on critical areas.

Why does this matter?

Because misalignment of even 0.05 mm between cavity and core can cause uneven pressure, leading to flash, wear, or parting line damage long before expected.

We also perform hardness and dimensional inspections at each stage to ensure that every component performs under repeated injection pressure — not just during the first trial.

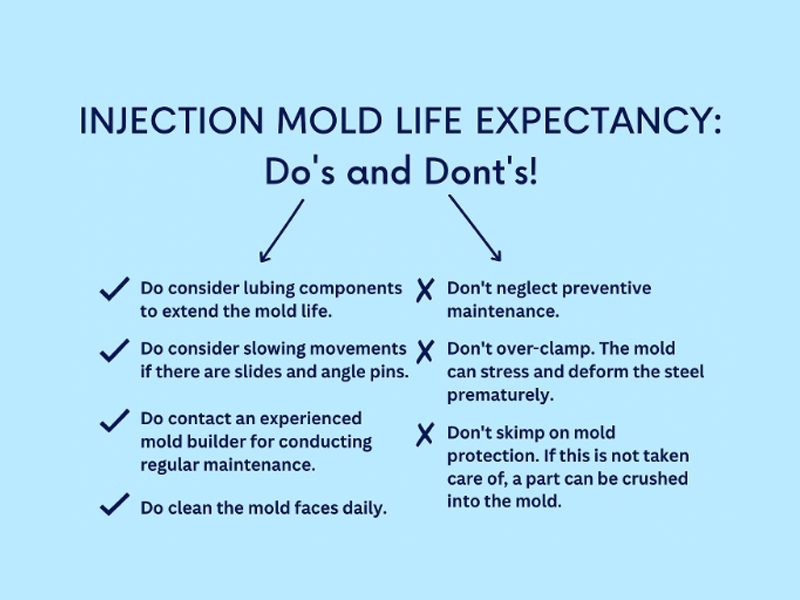

A well-maintained mold can last twice as long as a neglected one.

Unfortunately, this is where many mold users cut corners.

Preventive maintenance should include:

Regular cleaning of venting, runners, and ejector pins

Inspection for corrosion, scaling, or residue buildup

Polishing and lubrication of guide pins and slides

Replacing worn parts (like O-rings or seals) before they fail

At Alpinemold, we recommend that customers document each maintenance cycle and inspect high-wear zones (gates, slides, ejectors) every 50,000–100,000 shots.

We also provide maintenance schedules along with every mold we deliver — helping customers extend mold life beyond its expected classification.

When customers ask “how long does an injection mold last?”, we often start by referring to the SPI Mold Classification System — a well-recognized industry guideline that defines mold standards based on expected production volume, material hardness, and tooling requirements.

However, the SPI table is just the starting point.

In practice, real mold life often depends on material type, maintenance discipline, and molding conditions — not just the SPI class label.

SPI Class | Typical Lifespan (Shots) | Mold Base Material | Typical Use Case |

Class 101 | 1,000,000+ | Hardened steel (HRC 50+) | Continuous, high-volume production (e.g. automotive, medical) |

Class 102 | 500,000 – 1,000,000 | High-grade steel, possibly hardened | Medium to high volume, tight tolerances |

Class 103 | 100,000 – 500,000 | P20 or equivalent pre-hardened steel | Medium volume, consumer products |

Class 104 | 10,000 – 100,000 | Aluminum or soft steel | Low-volume runs, prototypes |

Class 105 | < 10,000 | Soft aluminum or epoxy | Prototype or short-run testing |

Engineer’s Tip:

These numbers are theoretical. Actual injection mold life expectancy can vary by ±50%, depending on:

Resin abrasiveness (e.g. glass fiber, flame-retardant additives)

Injection pressure and temperature control

Maintenance frequency

Surface treatment (e.g. nitriding, coating)

At Alpinemold, we often find that customers’ real-world molds don’t align perfectly with SPI classifications.

Here’s what we mean:

Customer Project | Intended Class | Actual Steel / Material | Mold Life Achieved | Key Takeaway |

Automotive interior vent | 102 | H13 + GF30% PA66 | 950,000 shots | Class 102 mold met spec with regular maintenance |

Medical housing | 103 | P20 + PC/ABS | 420,000 shots | Near theoretical range; required cavity polishing after 400K |

Consumer electronics shell | 102 | P20 (non-hardened) + PC+20%GF | 180,000 shots | Resin too abrasive for P20; reworked with H13 inserts |

Prototype lighting lens | 105 | Aluminum | 5,000 shots | Ideal for short-run validation only |

What this tells us is simple:

The SPI classification should guide budget and expectation,

but the real mold life is determined by engineering decisions — not the label.

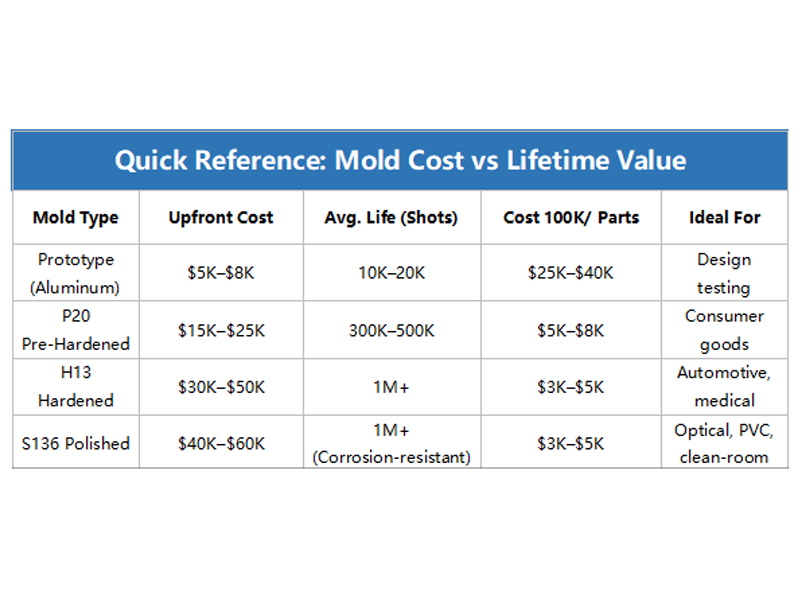

One common misunderstanding is that “longer mold life” always means “better mold.”

That’s not always true — because longer life usually means higher steel cost and machining time.

Here’s a simplified comparison for reference:

SPI Class | Estimated Mold Cost (Base) | Typical Lifespan | Cost per 100K Shots |

Class 105 | $3,000–$6,000 | <10,000 | $3,000+ |

Class 103 | $12,000–$25,000 | 300,000–500,000 | $5,000–$8,000 |

Class 101 | $35,000–$70,000 | 1,000,000+ | $3,500–$7,000 |

The lesson?

If you’re only producing 50,000–100,000 parts, investing in a Class 101 mold may not be economical.

But if your annual demand is in the hundreds of thousands, a hardened steel mold will actually lower your cost per shot over time.

At Alpinemold, our engineers help customers balance this equation — ensuring the mold fits the production goal, not just the catalog standard.

Even the best materials and machines can’t save a mold if critical engineering details are overlooked.

At Alpinemold, we’ve reworked many molds originally built elsewhere — and most failures trace back to just a few avoidable mistakes.

Here are the most common ones we see — and how we prevent them.

This is by far the #1 cause of premature wear.

Example:

A European customer once sent us a P20 mold for PA66 + 30% glass fiber parts.

After only 80,000 shots, the gate area and cavity surface were severely worn, causing flashing and poor part finish.

When we rebuilt the tool using H13 hardened inserts with nitriding treatment, the same design lasted over 900,000 shots with consistent dimensions.

Lesson:

Every resin behaves differently. Glass fibers, flame retardants, and corrosive additives all demand specific steels and surface treatments.

That’s why at Alpinemold, every new DFM review includes a material–steel compatibility check — so you never overpay or underbuild your mold.

Another common issue is when a mold looks fine on paper but fails due to thermal imbalance or gas traps.

Case Study:

A U.S. customer’s electronics housing mold showed burn marks after 40,000 cycles.

Our analysis found the root cause: insufficient venting near ribs and corners.

We redesigned the inserts with optimized vent depth (0.02 mm) and improved the cooling layout.

After modification, the new mold ran cleanly past 300,000 cycles, with faster cooling and shorter cycle time (by 12%).

Lesson:

Proper venting and cooling design not only prevent defects but also extend the life of cavity surfaces by reducing heat stress and polishing frequency.

Skipping simulation is like flying blind.

Without moldflow analysis, issues like unbalanced filling, high pressure points, and weld line concentration only show up after steel is cut — and by then, fixing them costs much more.

Example:

One customer insisted on skipping simulation to save time.

Their 8-cavity consumer product mold suffered uneven filling; two cavities wore out twice as fast as others due to localized pressure.

When we rebuilt it, our DFM + Moldflow optimization extended mold life from 150,000 to 650,000 shots — and reduced scrap rate by 40%.

Lesson:

Moldflow isn’t just for quality — it’s also for predicting mold wear and extending lifespan.

A mold isn’t a “build and forget” asset.

Even Class 101 molds degrade quickly if not cleaned and serviced on schedule.

We once received a high-volume automotive tool that started flashing after 200,000 cycles.

The design was solid — but ejector pins were dry, slides had buildup, and the cooling lines were partially blocked.

After ultrasonic cleaning and component replacement, the mold returned to normal operation and later reached 1.1 million cycles.

That’s why Alpinemold provides customers with a recommended maintenance plan, based on resin type and expected usage frequency.

We also label wear-prone zones and include spare inserts for high-wear areas — reducing downtime and keeping molds in production longer.

Choosing the right mold isn’t about buying the most expensive one — it’s about finding the sweet spot between cost, expected lifespan, and production goals.

At Alpinemold, we guide customers through this decision every day.

Here’s how we approach it from an engineer’s perspective.

Before talking about mold materials or SPI class, ask this simple question:

“How many parts do I really need — not just this month, but over the product’s full lifetime?”

Expected Production | Recommended Mold Type | Steel Material | SPI Class | Typical Lifespan |

< 10,000 shots | Prototype or bridge mold | Aluminum | Class 105 | 5,000–10,000 |

10,000–100,000 | Low-volume production | P20 | Class 104–103 | 100,000–400,000 |

100,000–500,000 | Medium-volume production | P20 or H13 | Class 103–102 | 300,000–800,000 |

500,000–1,000,000+ | Long-term production | H13 / S136 hardened | Class 102–101 | 800,000–1,500,000+ |

Pro Tip:

If you’re still validating a new product or market, we often recommend starting with a P20 or aluminum prototype mold, then upgrading to a hardened production mold after design freeze.

This avoids early overinvestment while still keeping you in control of time and quality.

Different plastics have different effects on steel wear.

Below is a simple reference we use internally at Alpinemold:

Resin Type | Wear / Corrosion Level | Recommended Steel | Surface Treatment |

ABS, PP, PE | Low | P20 | Polished |

PC, PMMA | Medium | H13 | Nitriding / Chrome |

PA66 + GF / PBT + GF | High (abrasive) | H13 / S136 | Nitriding or PVD |

PVC, Flame-Retardant | Corrosive | S136 / 420SS | Polishing + Coating |

Engineer’s insight:

We once helped a customer switch from P20 to H13 for a 30% GF nylon part — the cost increased by 15%, but the mold life extended 5×, and total cost per part dropped by 40%.

That’s why “cheaper steel” doesn’t always mean “lower cost.”

Even the best-built mold can fail early if it runs in poorly controlled conditions.

If your production facility has:

Hard water cooling

High humidity or limited maintenance intervals

Then corrosion-resistant steels like S136 or 420SS can save you downtime and polishing cost.

We also recommend using detachable inserts for high-wear zones — they’re easier to replace and greatly extend total tool life.

If you’re unsure how long your mold should last, ask your supplier for a mold life estimation report.

At Alpinemold, our engineers include this in every DFM package — detailing:

Expected number of cycles before major repair

Maintenance intervals

Steel hardness and coating specs

Cost-per-shot projection

This helps our customers see the long-term picture before committing to tooling.

Selecting the right mold is about engineering balance — not just cost.

The right combination of steel, surface treatment, and maintenance can turn a 200,000-shot mold into a million-shot performer.

That’s the kind of optimization we deliver at Alpinemold.

A: The lifespan of an injection mold varies widely depending on the steel material, design, and maintenance.

Prototype molds (like aluminum) typically last 10,000–50,000 cycles, while hardened steel molds (such as H13 or S136) can reach 1 million cycles or more with proper maintenance and stable processing conditions.

A: Early wear is usually caused by abrasive resins, poor venting, or inconsistent processing temperatures.

Materials with glass fiber, flame retardants, or high injection pressure can accelerate cavity wear if the wrong steel or coating is used.

Regular cleaning, polishing, and correct mold alignment are essential to prevent premature damage.

A: To extend mold life, focus on three key areas:

Material selection – use hardened steel for abrasive or high-volume parts.

Design optimization – include proper cooling, venting, and uniform wall thickness.

Maintenance – perform scheduled inspections and lubrication after every few thousand shots.A professional manufacturer like Alpinemold can help you create a maintenance plan that fits your production needs.

转换成博客的格式即可

A: Generally yes, but not always. Higher-cost molds use better steel, tighter tolerances, and advanced cooling systems, which lead to longer service life.

However, for low-volume production, a less expensive mold (like P20 or aluminum) may be more cost-effective.

The key is balancing mold cost vs. lifespan based on your production goals.

A: Prototype molds are made for short runs and product validation — typically aluminum or soft steel, with fewer cycles and lower cost.

Production molds, on the other hand, use hardened steel, better cooling, and precision finishing, designed for continuous, high-volume molding.

At Alpinemold, we help customers decide which type fits their project best by evaluating volume, resin, and part complexity.

The lifespan of an injection mold depends on smart design, the right material, and proper maintenance.

At Alpinemold, a trusted injection mold manufacturer in China with over 20 years of experience, we help customers extend mold life and reduce long-term production costs through expert engineering and DFM analysis.

Contact our team today for a free mold life assessment or DFM review — and discover how to make your molds last longer and perform better.