WhatsApp: +86 18126157548 Email: kerry@alpinemold.com

Our One-Stop Services: from reverse engineering to Injection Molding

Client Provided: A Physical Sample of Retractable Dog Leash

Client Country: United States

Mold Amount: 5 Sets

Mold Runner: Cold runner

Mold Steel: S136

Plastic Material:PA66+15%GF , PC

Why Us:

Expertise in glass filled nylon & PC moldingAdvanced equipment for tight tolerances

Competitive pricing & fast communication

| Availability: | |

|---|---|

Client Background

Our client is a leading U.S.-based company specializing in the manufacturing and sales of retractable dog leashes. To enhance product strength and longevity, they required glass filled nylon injection molding for durable, high-performance leash covers, along with precise PC components for a premium finish. The project demanded high-quality, intricate plastic parts that could withstand daily use while meeting strict aesthetic and functional requirements.

After evaluating multiple suppliers, the client chose Alpine Mold for our proven expertise in custom injection molding, high-precision mold manufacturing, and strong track record with PA66 + 15% GF injection molding and PC molding. In addition to our technical strengths, they appreciated our competitive pricing and timely, transparent communication, which fostered a smooth, efficient collaboration. Leveraging our one-stop service—from initial product optimization to final production—we helped the client bring their new retractable dog leash design to market quickly and with confidence.

Project Overview

The client approached Alpine Mold with physical samples of their existing retractable dog leash components, requesting our team to perform reverse engineering and create precise 3D designs for production. Based on these scanned and optimized designs, we produced five sets of injection molds for the leash cases, switch, hole covers, spring covers, protective jacket, and buttons.

We applied our expertise in nylon molding (PA66 + 15% GF) to manufacture strong, durable structural parts, and used PC molding for components requiring high clarity and exceptional impact resistance. Our engineering team designed and manufactured each mold with precision, then ran production on advanced Fanuc injection molding machines to deliver consistent, high-quality parts that met the client’s strict functional, aesthetic, and durability requirements.

Our Nylon Injection Molding Process

After reviewing the client’s requirements for strength and wear resistance, our engineering team recommended using the nylon injection molding process with PA66 + 15% GF (glass fiber-reinforced nylon) for the front and back leash cases and the protective jacket. The client agreed with our material choice, as this grade offers excellent impact resistance, abrasion resistance, and high strength—making it ideal for manufacturing high-durability structural components.

2. Complex Family Mold Design

The project included 16 retractable dog leash components, which we produced efficiently using 5 sets of family molds. By combining DFM analysis, mold flow simulation, and precision mold design, Alpine Mold optimized production, reduced costs, shortened timelines, and delivered molds that consistently produced high-quality retractable dog leash parts.

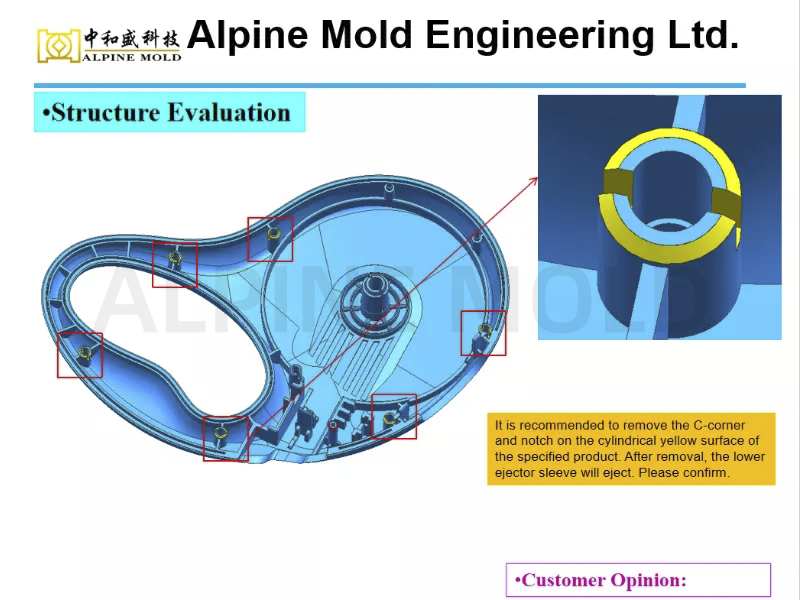

DFM Report

Before mold manufacturing began, our engineering team prepared a detailed Design for Manufacturability (DFM) report for each part. The report addressed:

Wall thickness and uniformity to prevent warpage, particularly for nylon plastic injection molding parts made from PA66 + 15% GF.

Draft angles to ensure easy part ejection without damaging textured surfaces.

Gate type and location to achieve balanced filling in multi-cavity family molds.

Assembly fit checks for front and back leash cases, ensuring precise alignment during production.

Leash Case (Front and Back Cases)

We designed the front and back cases as a 1+1 family mold using PA66 + 15% GF for glass filled nylon injection molding. This material provided high strength and durability, while a VDI 30 surface finish delivered an attractive, uniform texture. The family mold design ensured precise alignment and dimensional stability.

Other Components (Ring, Coil Spring, Board, Hole Cover)

These components were produced in a 1+1+1+1 family mold with glass filled nylon injection molding. This configuration allowed multiple parts to be molded in a single cycle, increasing productivity and ensuring consistent quality.

Switch, Hole Cover, and Button Components

We designed 3 additional family molds for these smaller parts, manufactured from PC (Polycarbonate). PC was selected for its excellent impact resistance and high-temperature tolerance, ensuring these parts could withstand repeated use under varying conditions.

Mold Flow Analysis

To ensure optimal mold performance, we conducted mold flow simulations for all molds. This analysis helped us:

Predict and eliminate potential defects such as air traps, weld lines, and short shots.

Optimize gate locations and runner layout for balanced filling in family molds.

Confirm uniform cooling to prevent warpage, especially in long and flat components like leash cases.

Minimize cycle time while maintaining high part quality.

Mold Design

Based on the DFM report and mold flow analysis results, we developed precise mold designs that included:

Cold runner systems for cost efficiency and stable molding quality.

S136 stainless mold steel for excellent wear resistance and corrosion protection, ideal for nylon moulding and pc moulding.

Precision alignment features to ensure perfect fit between mating parts.

Optimized venting to prevent burn marks, particularly for PC components.

3. Precision Mold Manufacturing & Surface Treatment

After the client approved the mold design, Alpine Mold began producing five sets of precision family molds using our advanced CNC machining centers, mirror EDM, wire-cut machines, grinding equipment, and high-precision CMM measuring systems for quality inspection. This combination of advanced processing and inspection capabilities enables us to maintain the tight tolerances required for glass filled nylon injection molding and pc injection molding.

CNC

EDM

For parts with high aesthetic requirements—such as the leash case—we applied a VDI 30 surface texture directly through our Charmilles EDM machines. This method eliminated the need for additional polishing, ensured a smooth and consistent finish, improved production efficiency, and shortened delivery times

4. Efficient Injection Molding Services

In addition to delivering high-precision mold design and manufacturing, Alpine Mold provided complete production services for this project. Using our advanced Fanuc injection molding machines, we produced 16 retractable dog leash components with consistent quality and repeatability.

For structural parts made through nylon injection molding with PA66 + 15% GF, we ensured exceptional strength and dimensional stability. For PC components, we achieved high clarity, impact resistance, and a flawless finish. Every part met the client’s strict standards for dimensional accuracy, aesthetic appeal, and long-term durability.

5. Strict Quality Control System

As a professional nylon injection molding factory and PC injection molding factory, Alpine Mold implements a comprehensive quality control system to ensure every component meets strict functional and aesthetic requirements. For this retractable dog leash project, we maintained precision and consistency across all 16 components—both structural PA66 + 15% GF parts and high-clarity PC parts—through the following QC stages:

Incoming Quality Control (IQC)

Conducted inspections when raw materials, purchased parts, or accessories arrived at the factory.

Checked plastic pellets (model, batch number, color, moisture content) to ensure they met specifications.

Verified purchased mold components (e.g., sliders, ejector pins, hot runner systems) for compliance.

Reviewed supplier documentation, including inspection reports, MSDS, RoHS, and COA.

In-Process Quality Control (IPQC)

Samples Checking: Verified first-shot dimensions, surface finish, and assembly fit with CMM and calipers before mass production.

Customer Sample Approval: Submitted initial molded samples to the client for confirmation before continuing production.

Process Inspection: Checked parts every two hours during production to monitor molding parameters and prevent defects such as warpage, flash, or color variation.

Assembly Fit & Surface Quality Inspection: Ensured precise component fit and uniform VDI 30 surface texture before packaging.

Final Quality Control (FQC)

Conducted inspections after all products were completed, before packaging or shipment.

Randomly checked dimensions, appearance, and assembly performance.

Verified labels, quantities, and packaging methods matched customer orders.

Inspected areas prone to damage during transportation, such as surface scratches or deformation.

Conclusion

Through reverse engineering, complex family mold designs, precise injection molding, careful material selection, and strict quality control, Alpine Mold delivered 16 high-quality retractable dog leash components for our U.S. client. Our focus on quality, reliability, and on-time delivery helped them launch a competitive product that meets both consumer expectations and industry standards.

As a professional glass filled nylon injection molding and pc injection molding company, we provide custom injection molding solutions that combine advanced equipment, proven project management, and deep material knowledge. Contact us today to turn your next pet product or any custom molding project into a market-ready success.